Product Introduction

Rapid quenching oil refers to quenching oil with a relatively fast cooling rate. It is suitable for quenching and cooling various materials with poor hardenability such as low-carbon alloy steel and carbon steel, as well as various thick and large-section workpieces; it can meet the requirements of these workpieces for higher quenching hardness and deeper hardened layer. The lower the viscosity of the rapid quenching oil, the more it is used for quenching and cooling in working conditions such as mesh belt furnaces that do not contact oxygen. For open quenching oil, consider using a rapid quenching oil with a slightly higher flash point, which also has a higher cooling rate. The operating temperature is 40-80 ℃ . The lower the flash point of the rapid quenching oil, the lower the temperature should be used.

Product Parameters

Name | Model | Flash Point (COC) °C | Kinematic viscosity @ 40°C (MM²/S) | Moisture | Thermal Oxidation Stability Viscosity Ratio> | Maximum Cooling Rate (°C/S) | Applicable Temperature (°C) |

Rapid quenching oil | Senco-O30A | 180 | 13-18 | trace | 1.25 | 105-110 | 40-80 |

Senco-O30B | 190 | 15-24 | trace | 1.25 | 105-110 | 40-90 | |

Senco-O30C | 210 | 22-30 | trace | 1.25 | 105-110 | 40-90 |

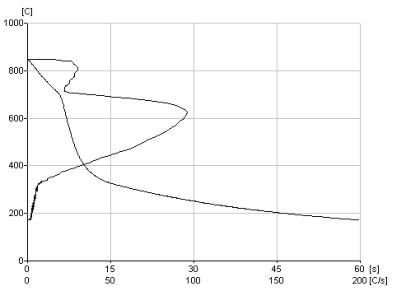

Cooling Curve

Scope Of Application

(1) Quenching of standard parts such as bolts, nuts, and washers.

(2) Quenching of thick and large-section workpieces.

(3) Quenching and cooling of various hardware tools.

(4) Overall quenching and tempering of bars and modules.

中文

中文 English

English Deutsch

Deutsch Français

Français Русский

Русский Español

Español