Product Information

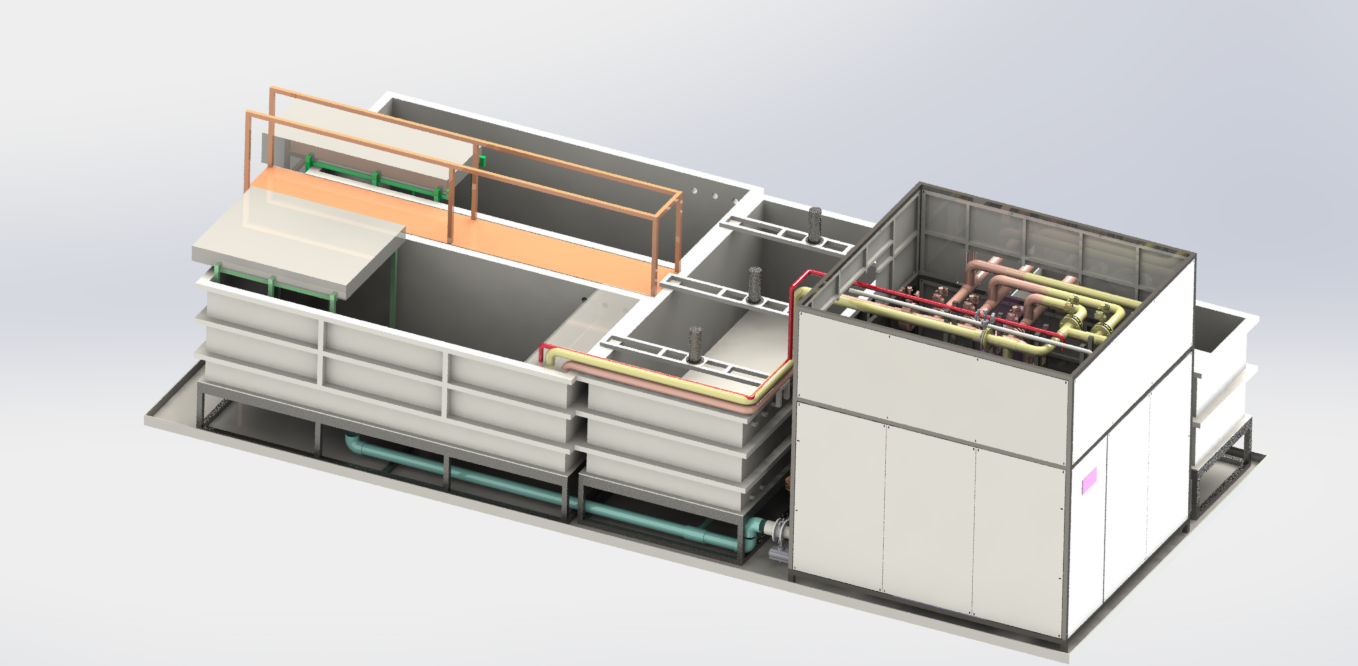

centralized cutting fluid supply and reflux purification of multiple machine tools . The equipment adopts PLC automatic control , does not require manual supervision, and has automatic liquid preparation , online flow , concentration, pH value monitoring , oil removal , slag removal, sterilization and deodorization, automatic constant pressure liquid supply, return liquid purification and other functions , realizing the automated management mode of cutting fluid use . Compared with traditional manual liquid preparation and liquid addition management , it effectively saves labor costs, cutting fluid use costs, tool wear costs, and waste liquid treatment costs , so that the performance of the cutting fluid can be fully utilized, thereby improving product processing efficiency and product quality.

Applicable scenarios: Factories with a large number of CNC machines

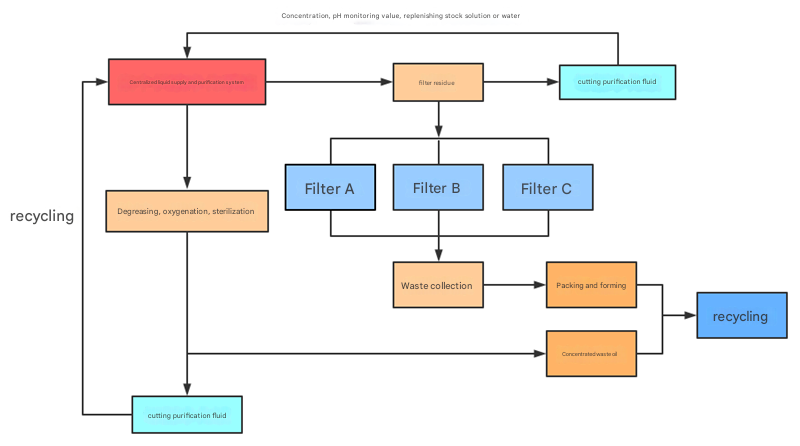

Centralized liquid supply purification system work flow chart

Benefit Analysis

Artificial liquid preparation | Centralized liquid supply purification system |

The accuracy of the ratio concentration is about 70~80% | Flow monitoring ratio concentration accuracy reaches 99% |

It takes a long time and the fluid is not replenished in time. The average time is about 10~20 minutes/unit | Automatic replenishment when liquid is insufficient, saving time and effort |

60 units/person are needed for liquid preparation | Unmanned operation (automatic control) |

The cutting fluid in the water tank cannot be effectively purified, and the impurities and waste oil in it are mixed, causing the tool to wear faster. | Regular return and purification of liquid effectively ensures the quality of cutting fluid, reduces tool wear by 5~15% , and effectively improves machining accuracy |

Cutting fluid is easy to deteriorate and stink, and the service life of cutting fluid is reduced | Centralized purification, degreasing and deodorization, effectively extending the life of cutting fluid by 20~30% |

The effective utilization rate of the stock solution is about 70~80% | Realize online monitoring of pH value, temperature, concentration detection, etc., and the effective utilization rate of stock solution reaches more than 90% |

中文

中文 English

English Deutsch

Deutsch Français

Français Русский

Русский Español

Español